Testifying before the U.S Senate Committee on Energy and Natural Resources in February 2019, ARPN expert panel member and managing director of Benchmark Mineral Intelligence Simon Moores sounded the alarm on the supply chains of metals and minerals that are key components of battery technology and energy storage.

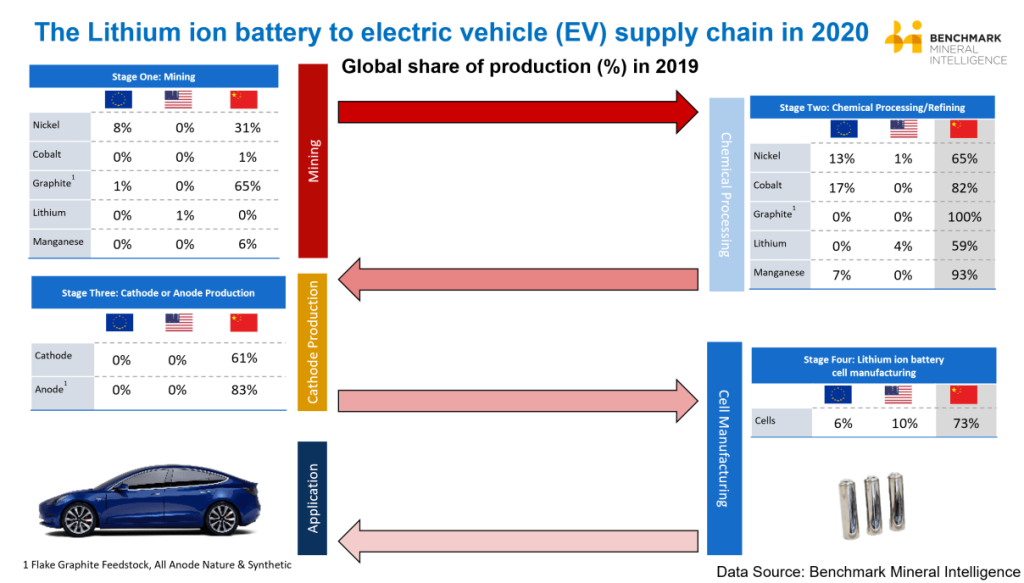

Arguing that we were in the middle of a global battery arms race, in which so far the US was a bystander, Moores provided several insightful visuals to outline “the control that China exerted on the lithium ion battery to electric vehicle (EV) supply chain” – specifically for lithium, cobalt, graphite and nickel.

Benchmark Mineral Intelligence has since updated these visuals and included 2019 data for the full annual year and included manganese as a “key input to NCM (nickel cobalt manganese) cathodes.”

The verdict is striking: Both Europe and the United States are “sorely missing” the chemical links in the supply chain necessary to create a “21st century EV ecosystem on their respective continents should the situation continue unchecked.”

Specifically, for manganese, North America accounted for zero tonnes of production which Europe registered fractional tonnage (which however is unsuitable for battery cells).

China, while only producing 6% of global total output, has a “significant advantage” in the manganese chemical refining step in the supply chain accounting for 93% of production in 2019. According to Benchmark Mineral Intelligence, “[t]his is is a larger imbalance than cobalt of which China similarly mines a fraction, 1% of global supply, but chemically refines 82%.”

As policy makers work to strengthen domestic supply chains in the coming months, this is an important point to remember: The U.S. is in the fortunate position to be rich in metals and minerals.

ARPN’s Daniel McGroarty recently pointed out:“[T]he U.S. is resource rich, geologically blessed with known resources of at least 32 of the 35 critical minerals, with deposits of heavy rare earths in Texas, graphite in Alaska, manganese in Arizona – not to mention innovative methods to recycle and recover critical minerals from spent EV batteries, rhenium for jet fighter engines from copper waste in Utah, and all manner of critical minerals from coal waste in Pennsylvania that’s never been considered as a potential supply source.“

We should harness this vast mineral potential where possible.

However, it is critical to not only focus on resource extraction, but look at the supply chain as a whole — because as Benchmark Mineral Intelligence makes clear: “you do not need to own the raw material sources to control the global flow of trade in the lithium ion battery supply chain.”