The global push towards net zero carbon marches on, and with sales of EVs continuing to soar even as prices rise, analysts suggest that the “world could be nearing a critical electric vehicle sales tipping point, when volatile adoption trends are overtaken by mainstream demand.”

With skyrocketing demand, the mineral intensity of the green energy transition and supply chain challenges associated with our over-reliance on adversary nations, most notably China, has finally resonated with stakeholders. The passage of the Bipartisan Infrastructure Law in the summer of 2021 represented an important step towards decoupling U.S. critical mineral supply chains from adversary nations. Others have since followed.

Today marks another key step: As part of the implementation of the 2021 infrastructure law, the U.S. Department of Energy announced the first round of funding under the Act for projects aimed at “supercharging” U.S. manufacturing of batteries for electric vehicles and electric grid.

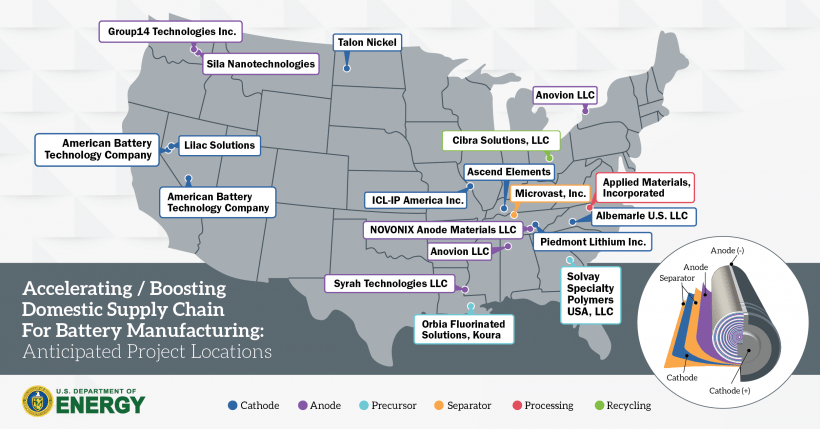

Awardees — a total of 20 companies — will receive a combined $2.8 billion “to build and expand commercial scale facilities in 12 states to extract and process lithium, graphite and other battery materials, manufacture components, and demonstrate new approaches, including manufacturing components from recycled materials.”

According to the Department of Energy announcement, recipients will match the federal funds to leverage a total of more than $9 billion “to boost American production of clean energy technology, create good-paying jobs, and support President Biden’s national goals for electric vehicles to make up half of all new vehicle sales by 2030 and to transition to a net-zero emissions economy by 2050.”

The supported projects span the entire value chain, with funding going towards:

- Developing enough battery-grade lithium to supply approximately 2 million EVs annually

- Developing enough battery-grade graphite to supply approximately 1.2 million EVs annually

- Producing enough battery-grade nickel to supply approximately 400,000 EVs annually

- Installing the first large-scale, commercial lithium electrolyte salt (LiPF6) production facility in the United States

- Developing an electrode binder facility capable of supplying 45% of the anticipated domestic demand for binders for EV batteries in 2030

- Creating the first commercial scale domestic silicon oxide production facilities to supply anode materials for an estimated 600,000 EV batteries annually

- Installing the first lithium iron phosphate cathode facility in the United States

The map provides a snapshot of anticipated project locations:

More details and individual project information can be accessed here.

According to DoE, the department “anticipates moving quickly on additional funding opportunities to continue to fill gaps in and strengthen the domestic battery supply chain,” and ARPN will continue to keep tabs on these efforts.